Acrylic, a versatile and widely embraced material, has found its place in numerous industries, ranging from art and design to engineering and manufacturing. However, when combined with laser technology, acrylic takes on an entirely new dimension, unlocking its potential for intricate and precise creations. In this article, we will delve into 20 innovative acrylic laser projects that exemplify the extraordinary possibilities inherent in this material and the laser cutting process. These projects not only showcase the fusion of creativity and technology but also demonstrate how acrylic and lasers can produce remarkable artwork and functional objects.

How to embark on acrylic laser projects?

Embarking on acrylic laser projects entails a series of steps. Here is a general outline of the process:

1. Design

Begin by crafting a design for your project using computer-aided design (CAD) software. Specialized software options like AutoCAD or Adobe Illustrator can be employed to bring your vision to life. Take into consideration factors such as size, shape, and intricacy while conceptualizing your design.

2. Material Selection

Select the most suitable acrylic sheet for your project. Acrylic is available in various thicknesses and colors. While clear acrylic sheets are commonly used, you also have the option to choose colored or translucent acrylic, depending on your design preferences.

3. Acrylic Laser Cutting

Once you have finalized your design and acquired the necessary acrylic sheet, you will require a laser cutter or engraver. These machines utilize a focused laser beam to precisely cut or engrave the acrylic. It is crucial to ensure that your laser cutter is compatible with acrylic materials and possesses the required power and settings for the thickness of your chosen acrylic sheet.

a. Laser cutter setup

Follow the manufacturer’s instructions for setting up your laser cutter. Proper calibration and functioning of the ventilation system are essential.

b. Preparing the acrylic sheet

Thoroughly clean the acrylic sheet to eliminate any dust or debris. Place it securely on the laser cutter’s bed, ensuring it lies flat. If necessary, utilize clamps or tape to secure it in place.

c. Configuring laser settings

Adjust the laser settings to correspond with the thickness and type of acrylic being used. The laser power, speed, and focus should be optimized for clean and precise cuts or engravings. Consult the laser cutter’s manual or seek guidance from experienced users if required.

d. Performing the Cutting Process

Begin by uploading your design file into the software of the laser cutter. Take extra care to verify the positioning and alignment of the design on the acrylic sheet. Initiate the cutting process and diligently oversee the laser cutter’s progress to ensure that everything proceeds according to plan.

4. Final Touches

Once the laser cutting is finished, cautiously extract the acrylic pieces from the machine. Utilize a soft cloth to eliminate any residue or debris from the cut edges. If desired, you can refine the edges with either a flame or a specialized polishing tool designed specifically for acrylic.

5. Construction and Presentation

For projects involving multiple acrylic pieces, adhere to the assembly instructions for joining them together. This may involve techniques such as gluing, heat bending, or using specialized acrylic adhesives. Once assembled, proudly display your acrylic laser project in a suitable location or utilize it for its intended purpose.

Top 15 Exceptional Ideas for Acrylic Laser Projects

1. Laser-Cut Acrylic Jewelry

Laser cutting has revolutionized the creation of intricate and exquisite acrylic jewelry pieces. From earrings to necklaces, laser-cut acrylic can fashion breathtaking designs with intricate patterns and precise shapes, offering a distinctive accessory for fashion enthusiasts.

2. Acrylic Architectural Models

Laser cutting empowers architects to fashion detailed and accurate architectural models. Acrylic proves to be an ideal material for this purpose, as it can be effortlessly engraved and cut to replicate intricate building structures, showcasing designs to clients and stakeholders.

3. Acrylic Wall Art

Artists have wholeheartedly embraced laser cutting as a medium to craft captivating wall art. Acrylic sheets can be intricately cut into elaborate designs, enabling artists to experiment with diverse patterns and textures. Illuminating the acrylic from behind adds another dimension to the artwork, creating a mesmerizing visual spectacle.

4. Acrylic Signage

Laser cutting finds extensive application in the production of acrylic signage. Whether it’s business logos or directional signs, laser-cut acrylic offers a professional and refined appearance. The precision cutting and engraving capabilities ensure clear and legible signage.

5. Acrylic Delights for Your Home Decor

Embrace the allure of laser-cut acrylic and discover a world of unique and captivating home decor pieces. From enchanting lampshades to exquisite coasters, the possibilities are boundless. Immerse yourself in the realm of intricate engravings on acrylic surfaces, where ordinary objects are transformed into extraordinary artistic statements.

6. Magnificent Trophies and Awards in Acrylic

Unleash the versatility of laser-cut acrylic and witness the creation of awe-inspiring trophies and awards. With acrylic’s flexibility, we can craft custom shapes and sizes that perfectly suit your vision. The addition of laser engraving adds a personal touch, resulting in stunning and enduring accolades that effortlessly stand out.

7. Custom Electronics Enclosures in Acrylic

Experience the unparalleled precision of laser cutting with acrylic, making it the ideal material for crafting tailor-made electronics enclosures. Whether it’s a computer case or a smartphone stand, laser-cut acrylic ensures a flawless fit while exuding a sleek and contemporary aesthetic.

8. Enchanting Decorative Screens in Acrylic

Let the enchantment of laser-cut acrylic breathe life into your indoor and outdoor spaces through captivating decorative screens. These versatile screens can serve as room dividers, privacy shields, or outdoor installations. The intricate patterns allow light to dance through, casting mesmerizing shadows and creating a symphony of delightful designs.

9. Timeless Acrylic Clocks

Witness the metamorphosis of laser-cut acrylic into extraordinary and stylish clocks. The precision cutting technique allows for intricate clock face designs, while the transparent nature of acrylic enhances the overall aesthetic. These acrylic clocks transcend functionality, becoming pieces of art that mesmerize and captivate.

10. Functional Art: Acrylic Coasters and Placemats

Elevate your dining experience with laser-cut acrylic coasters and placemats that redefine functionality. Etched with intricate designs, these conversation starters add a touch of elegance to any dining table or coffee bar, marrying practicality with artistic expression.

11. Personalized Keychains and Accessories in Acrylic

Unleash your individual style with laser-cut acrylic keychains and accessories, offering a delightful and personalized way to showcase your uniqueness. From personalized names to intricate shapes, these lightweight and durable acrylic keychains can be fully customized to reflect your personality.

12. Elegant Acrylic Bookmarks

Bid farewell to traditional paper bookmarks and embrace the trendiness of laser-cut acrylic bookmarks. These elegant alternatives can be designed with intricate shapes and patterns, adding a touch of sophistication to your favorite books.

13. Sleek Business Card Holders in Acrylic

Make a lasting impression with sleek and professional business card holders crafted through the art of laser cutting acrylic. Functionality meets visual appeal, creating an eye-catching accessory that complements your professional image.

14. Artistic Acrylic Wall Mirrors

Unleash your creativity and design acrylic frames for wall mirrors that embody modernity and artistry. Incorporate intricate patterns or geometric shapes, turning your wall mirrors into captivating focal points that redefine your space.

Embrace the enchantment of laser-cut acrylic and let your imagination run wild as you transform everyday objects into extraordinary works of art.

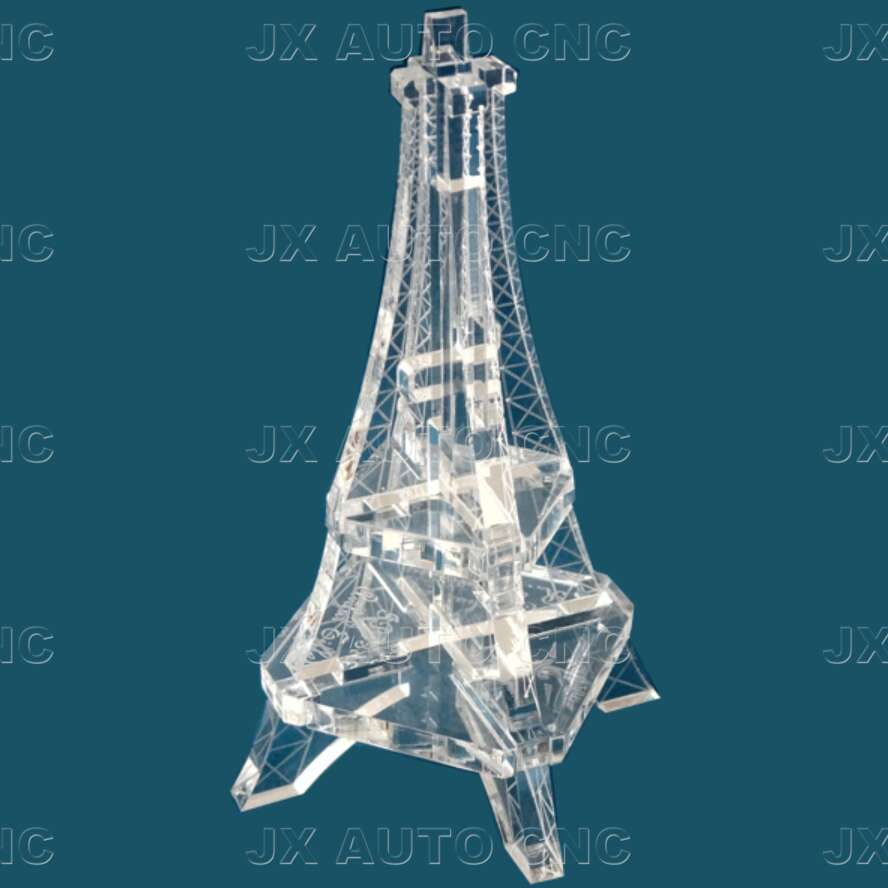

15. Acrylic 3D Puzzle Creations

Imagine the wonder of crafting intricate 3D puzzles using laser-cut acrylic sheets. With interlocking pieces, you can bring to life animals, buildings, and objects, offering a captivating and visually stunning challenge.

16. Sleek and Professional Acrylic Business Card Holders

Elevate your professional image with our laser-cut acrylic business card holders. Designed to be both functional and visually appealing, these holders exude sophistication and style.

Choosing the Perfect Acrylic Laser Cutting Machine

When it comes to selecting the ideal acrylic laser cutting machine, several crucial factors must be considered. Laser power, cutting speed, software capabilities, working area, stability, and safety are all essential aspects to evaluate. Taking these into account, I highly recommend the remarkable CO2 acrylic laser cutting machines from JX AUTO CNC.

Unleash Efficiency with the Double Head 1390 Acrylic Laser Cutter

Experience the ultimate in CNC laser cutting technology with our double head 1390 acrylic laser cutter. Equipped with two CO2 laser tubes, this innovative machine delivers high power for swift and precise acrylic material cutting. With the ability to simultaneously cut two working areas, production efficiency is significantly enhanced, reducing processing time and maximizing productivity.

parameters

| Model | Laser engraving machine1390 |

| Working area | 130cm*90cm |

| Equipment Dimension | 205cm*180cm*157cm |

| Laser power | 60/80/100W |

| Laser type | CO2 sealed laser tube,water-cooled |

| Engraving speed | 0-6000cm/min |

| Cutting speed | 0-5000cm/min |

| Power supply | 220V/50HZ , 110V/60HZ |

| Graphic format supported | BMP, PLT, DST, DXF, AI |

| Software supported | CorelDraw, PhotoShop, AutoCAD,TAJIMA |

| Driving system | stepper motor |

| Net Weight | 530kg |

| Optional parts | Up-down worktable,Rotary axis |

| Applicable material | Acrylic, crystal, glass, ceramic, marble, metal coating, cloth, fabric, wood e |

Benefits

Unmatched Production Flexibility

Experience unparalleled flexibility with the double-head CO2 laser cutting machine, allowing for easy adjustment of the cutting head’s position and working mode. Whether you require single-head or double-head operation, this machine provides exceptional production flexibility and adaptability to meet diverse cutting needs.

Unrivaled Cutting Precision

Achieve astonishing precision with the double-head CO2 laser cutting machine. Its dual-head configuration enables the cutting of intricate shapes and intricate details with utmost accuracy. By minimizing cutting errors and enhancing precision, this machine delivers superior cutting results with unparalleled finesse.

Time and Cost Savings

Maximize your efficiency and cost-effectiveness with the double-head CO2 laser cutting machine. By simultaneously cutting two workpieces, it significantly reduces production time and costs. For large-scale projects demanding high efficiency, the double-head design offers substantial economic benefits, making it an ideal choice.

1325 Hybrid CO2 Laser Cutter for Acrylic

Experience the versatility of the 1325 hybrid CO2 laser cutter, capable of handling diverse cutting requirements across various materials such as acrylic, wood, metal, leather, paper, fabric, and more.

parameters

| Model | JX-1326 |

| Processing area | 1300mm*2600mm |

| Color | Blue and white |

| Control System | RUIDA |

| Laser power | RECI W6 |

| Laser type | Sealed Co2 glass laser tube |

| Cutting speed | 0-30,000mm/min |

| Cutting thickness | 0-25mm acrylic (others determined by materials) |

| Position system | Red dot |

| Support graphic format | DST, PLT, BMP, DXF, etc. |

| Motor&drive | stepper |

| Working voltage | 220V,50Hz,Single-phase |

| Working table | Blades working table |

| Packing | wooden box |

| Accessory | Air Pump, Fan, CW5000 Water cooler, 130w Laser power supply,lens |

| Application | Cut (acrylic, plexiglass, wood, MDF, textile) Engrave(wood,stone) |

| Operating temperature | 0-45℃ |

| Operating humidity | 5-95% |

Advantages

Exceptional Adaptability

The hybrid CO2 laser machine offers unparalleled adaptability by allowing flexible adjustment of laser parameters and beam characteristics to suit different materials and processing requirements. With adjustable power, pulse frequency, and beam focus, it effortlessly meets diverse cutting and processing needs, ensuring optimal results.

Energy Efficiency

Embrace the energy-saving benefits of CO2 laser technology. The hybrid CO2 laser machine utilizes a non-contact cutting method, eliminating the production of dust, exhaust gases, and waste liquids. Compared to traditional cutting methods, it boasts lower energy consumption and reduced environmental pollution, making it an environmentally friendly and energy-efficient option.