JX-Flying Laser Marking Machine for Production Line High Quality Laser Marking Machine

Price Range : $1821/ Set based on the configuration

Price Range : $10000 to $20000/ Set based on the configuration

Brand : Jx Auto CNC

Model : JX-3015

Category : Laser Machine-Fiber Laser

Payment: TT, Visa, Mastercard, Credit Cards, Paypal

Supply Ability : 200 Sets In Stock / Month

Policy : Shopping, Return, Refund Policy

New metal sheet and tuber laser cutting machine is an ideal entry-level laser cutting machine without any high purchase cost or training cost. It has easy operation and simple maintenance. One machine integrates two functions, reducing the floor space and improving efficiency.

1. One machine with dual functions, saving cost It can cut both metal sheets and pipes. Besides, the two-in-one design saves a lot of floor area and improve work efficiency greatly.

2. Aircraft-grade aluminum beam Aircraft-grade aluminum is corrosion resistant, lightweight and highly rigid, guaranteeing high speed laser cutting. Besides, it also guarantee the excellent cutting precision due to the perfect dynamic performance such as anti-twisting, anti-tilting and anti-deformation.

3. High quality thick wall carbon steel sheet welded bed High strength machine bed is more stable and durable. After 600℃ stress relief annealing treatment, the machine bed has strong structural rigidity. The overall mechanical structure of the machine has small deformation, low vibration, ensure cutting accuracy.

4. Independent control cabinet All electrical components and laser sources are built into a separate control cabinet to prevent dust buildup. Besides, the control cabinet is equipped with automatic thermostatic air conditioning. This prevents damage to components from high summer temperatures.

5. Integrated large volume dust removal system The dust removal system can remove all the smoke generated from the cutting process with large air volume. This helps protect the operator’s health and the working environment.

| Model | JX-3015 | JX-1560 | JX-2060 |

| Working area(mm) | 1515*3030 | 1515*6050 | 2020*6050 |

| Worktable bearing capacity | 900kg | 1500kg | 2000kg |

| Positioning accuracy | ±0.03mm | ±0.03mm | ±0.03mm |

| Repositioning accuracy | ±0.02mm | ±0.02mm | ±0.02mm |

| Pipe section shape | Round/square/rectangular | Round/square/rectangular | Round/square/rectangular |

| Max.length of pipe | 3m/6m | 3m/6m | 3m/6m |

| Laser power | 1kW-6kW | 1kW-6kW | 1kW-6kW |

| Laser | Multiple options | Multiple options | Multiple options |

| Max.acceleration | 1.5G | 1.5G | 1.5G |

| Max.running speed | 140m/min | 140m/min | 140m/min |

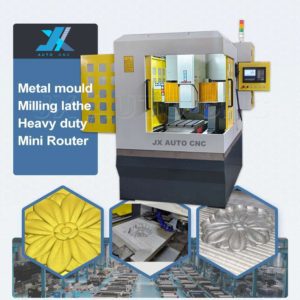

1、I need a CNC router, can you give me some suggestions?

A : Sure, we will give suggestions of the most suitable machine. Beforethat, we need to knowsome information, such as effective processingarea, materials, etc., to determine the main parameters.

2. Which kind of materials can be processed on this machine?

A: Wood, mdf, stone, acrylic, glass, plastic, foam, aluminium, copper.

and almost all kinds of non-steel materials.

3. Are you a factory or trading company?

A : We are the manufacturer and we have 10 years factory experienceAs only the machine made byourself, the quality can be trusted, andthe most important thing is that we can do better after-salesserviceWe know how to fix the problem of every part easliy, so welcome tovisit to our factory.

4.How should I pay for my order ?

A : You need to pay 30% as prepayment at first, then we will start to makeproduction. When themachine is completed, we will send pictures orvideos to you, and then you need to pay the balance.We will ship themachine to you after we receive your full payment.

5.How long is the delivery time?

A : For standard machines it will be 7-10 davs: For non-standard machinesand customized machinesaccording to cients’ specific requirements. itwill be 15 to 30 days.

Therefore, with the above processing advantages, this type of laser cutter machine is widely used in advertising sign production, sheet metal structure, high and low voltage electrical cabinet production, textile machinery parts, kitchenware, automobiles, machinery, elevators, electrical parts, spring sheets, subway parts, etc.

Price Range : $1821/ Set based on the configuration

Price Range : $3500/ Set based on the configuration

Price Range : $4500/ Set based on the configuration

Price Range : $4500/ Set based on the configuration

Price Range : $4200/ Set based on the configuration

Price Range : $3300-$3500/ Set based on the configuration