JX-Flying Laser Marking Machine for Production Line High Quality Laser Marking Machine

Price Range : $1821/ Set based on the configuration

Price Range : $20000 to $29000/ Set based on the configuration

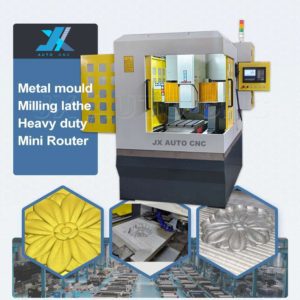

Brand : Jx Auto CNC

Model : JX-2030

Category : CNC Tools -Water Jet

Payment: TT, Visa, Mastercard, Credit Cards, Paypal

Supply Ability : 200 Sets In Stock / Month

Policy : Shopping, Return, Refund Policy

5 axis water jet cutting machine unlike a conventional 3-axis waterjet cutting machine, this product is added with A-axis (in a vertical direction) and C-axis (which rotates around the Z axis).By using state-of-the-art technology and the Italian ECS control system, it can produce 0-±45° inclined cuts with a maximum rotation angle of up to ±540°. Currently, this state-of-the-art cutting equipment has been applied by a wide variety of advanced processing industries. It can cut the product cross section without inclination, and cut bevel at any angle, as well as cut the workpiece vertically, especially cut cone, curved impeller, gear, etc.

1.Steel base of machine structure

2.Cantilever /Fly-arm made of Seamless cold-rolled manganese steel with 10mm thickness

3.No gap movement make sure machine move steady

4.Stainless steel dustcover protect drive system with long lift

5.Working table made by carbon steel with 5mm thickness

6.Working table apart from machine can keep cutting accuracy because no vibration effects

7.Automatic lubrication pump make drive system Real-time lubrication

| Machine Model | JX 1325/1530/2030 |

| Working Area(length * width) | 1300*2500/1500*3000/2000*3000MM |

| Cutting method | Plasma Source |

| Table | Blade Table(Sawtooth table is optional) |

| Power | 63A (A/85A/105A/125A/200A is optional) |

| Cutting Speed | 0-8000mm/min |

| Control System | Starfire+THC Controller |

| Frame | General Duty Frame |

| Power Supply Requirement | 220V(110V/380V is optional) |

| Use of the Environment | Clean and Dust Free or Dust less |

| Controlling Software | Fastcam |

| Motor | Stepper Motor& Driver;Servo Motor&Driver |

| Files Transfer | USB |

| Machine Power | <2000W |

| Running Accuracy | ≤0.1mm |

| Transmission | Gear Transmission |

| Power Supplier | China Huayuan Supplier(Ameican Hypertherm Power Supplier is optional) |

| Optional parts | Rotary/flame cutting head/heavy duty frame/huayuan power supplier/sawtooth table |

1、I need a CNC router, can you give me some suggestions?

A : Sure, we will give suggestions of the most suitable machine. Beforethat, we need to knowsome information, such as effective processingarea, materials, etc., to determine the main parameters.

2. Which kind of materials can be processed on this machine?

A: Wood, mdf, stone, acrylic, glass, plastic, foam, aluminium, copper.

and almost all kinds of non-steel materials.

3. Are you a factory or trading company?

A : We are the manufacturer and we have 10 years factory experienceAs only the machine made byourself, the quality can be trusted, andthe most important thing is that we can do better after-salesserviceWe know how to fix the problem of every part easliy, so welcome tovisit to our factory.

4.How should I pay for my order ?

A : You need to pay 30% as prepayment at first, then we will start to makeproduction. When themachine is completed, we will send pictures orvideos to you, and then you need to pay the balance.We will ship themachine to you after we receive your full payment.

5.How long is the delivery time?

A : For standard machines it will be 7-10 davs: For non-standard machinesand customized machinesaccording to cients’ specific requirements. itwill be 15 to 30 days.

The diversity of materials that can be cut with a waterjet cutter is one of the most attractive capabilities of this technology. Waterjet cutting processes can cut different materials based on strength, durability, corrosion resistance, and conductivity including:

Metals – Waterjet cutters are capable of cutting all types of metals including hardened tool steel, aluminum, titanium, carbon steel, stainless steel, and red metals (copper, brass, and bronze).

Naturals – Waterjet cutting machines use specialized techniques such as low-pressure pierce, water-only cutting, and vacuum assistance to cut a wide array of natural materials including glass, stone, wood, leather, and ceramics.

Composites – Waterjet cutters precisely cut any fiber-reinforced material, including carbon fiber, fiberglass, and Kevlar reinforced personnel armor. Waterjet cutters are able to quickly and cleanly cut composites without the drawbacks that come with conventional machining such as tooling changes and restrictions due to heat buildup.

Plastics & Rubber – Waterjet cutting allows for efficient and precise cutting of plastic and rubber materials such as foam, rubber, linoleum, Plexiglas, polycarbonates, and acrylic. Businesses that use waterjet cutting can navigate around the material distortion barrier that is often encountered while machining plastic on conventional Computer Numerical Control (CNC) machines by using the cold cutting method of a waterjet cutter.

Price Range : $1821/ Set based on the configuration

Price Range : $3500/ Set based on the configuration

Price Range : $4500/ Set based on the configuration

Price Range : $4500/ Set based on the configuration

Price Range : $4200/ Set based on the configuration

Price Range : $3300-$3500/ Set based on the configuration