JX-Flying Laser Marking Machine for Production Line High Quality Laser Marking Machine

Price Range : $1821/ Set based on the configuration

Price Range : $6000 / Set based on the configuration

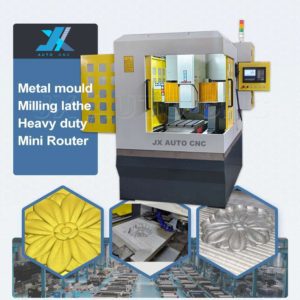

Brand : Jx Auto CNC

Model : JX-2030

Category : CNC Router-ATC CNC

Payment: TT, Visa, Mastercard, Credit Cards, Paypal

Supply Ability : 200 Sets In Stock / Month

Policy : Shopping, Return, Refund Policy

This 2030 ATC CNC router is one of the most classic and popular CNC among the tool change engraving machines. It adopts the linear tool change mode with a fast tool change speed, and the tool change can be completed within a few seconds without any people’s operation, which greatly improves productivity.

1. Vacuum table saves time of fixing workpiece such as MDF plate on the table.

2. 9kw air cooling spindle, powerful and the cutting ability in the workpiece is stronger.

3. The CNC machine is equipped with a separate control cabinet, more convenient in terms of operation and maintenance.

4. This machine has always been well received by large companies or someone with diverse processing needs.

| Model | JX1325ATC |

| X,Y axis travel | 300x2500mm, option: 1500*3000mm; 2000*3000mm; 2000*4000mm, etc. |

| Z axis travel | 200mm, option: 300mm, 400mm, etc. |

| Spindle type | 9kw ATC air cooling spindle,18000rpm, ER32 collets |

| Inverter type | 11kw |

| Drilling bank | Optional |

| Tool magazine | Linear tool magazine Option: Carousel type auto tool changer |

| Tool holder with collet | ISO30, ER32 collet: φ4, φ6, 1/8, 1/2 |

| Control system | Taiwan LNC controller optionTaiwan SYNTEC controller |

| Driving system | 850w Leadshine AC servo option:850w Yaskawa servo motor |

| Reducer | Reducer |

| Machine structure | Heavy duty body |

| Work table | Aluminum T-slot & vacuum work table |

| Positioning cylinder | Optional: 5 pieces (X2,Y3) |

| Linear guide | Taiwan Original Linear guide |

| Transmission | X, Y axis: Taiwan /Germany helical rack and pinion Z axis: Taiwan TBI high precision ball screw |

| Lubrication system | Automatic lubrication system |

| Tool calibration | Auto tool sensor calibration |

| Cables | Germany Igus cables with CE, cUL certificate |

| Compatible software | Artcam, Alphcam, Type 3, Ucancam, Aspire, etc. |

| Command language | G Code & M Code |

| Traveling speed | 60m/min |

| Working speed | 0-25m/min |

| Re-positioning accuracy | ±0.03mm |

| System resolution | ±0.0025mm |

| Working accuracy | ±0.07mm |

| Working air pressure | 0.8MPa |

| Working voltage | 220V 1PH/3PH 50HZ/60HZ 380V 3PH 50HZ/ 60HZ |

1、I need a CNC router, can you give me some suggestions?

A : Sure, we will give suggestions of the most suitable machine. Beforethat, we need to knowsome information, such as effective processingarea, materials, etc., to determine the main parameters.

2. Which kind of materials can be processed on this machine?

A: Wood, mdf, stone, acrylic, glass, plastic, foam, aluminium, copper.

and almost all kinds of non-steel materials.

3. Are you a factory or trading company?

A : We are the manufacturer and we have 10 years factory experienceAs only the machine made byourself, the quality can be trusted, andthe most important thing is that we can do better after-salesserviceWe know how to fix the problem of every part easliy, so welcome tovisit to our factory.

4.How should I pay for my order ?

A : You need to pay 30% as prepayment at first, then we will start to makeproduction. When themachine is completed, we will send pictures orvideos to you, and then you need to pay the balance.We will ship themachine to you after we receive your full payment.

5.How long is the delivery time?

A : For standard machines it will be 7-10 davs: For non-standard machinesand customized machinesaccording to cients’ specific requirements. itwill be 15 to 30 days.

Automatic tool changer (ATC) CNC Router machine is suitable for the processing of various complex products or a variety of processing. It can be equipped with 6, 8, 10, 12 tools according to the different production process requirements of customers. There are two tool change modes for inline tool change and disc tool change. Widely used, including engraving, milling, chamfering, side milling, drilling, cutting, grooving, etc.

Price Range : $1821/ Set based on the configuration

Price Range : $3500/ Set based on the configuration

Price Range : $4500/ Set based on the configuration

Price Range : $4500/ Set based on the configuration

Price Range : $4200/ Set based on the configuration

Price Range : $3300-$3500/ Set based on the configuration